National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

Thread ball valve

Location:Home > Thread ball valve

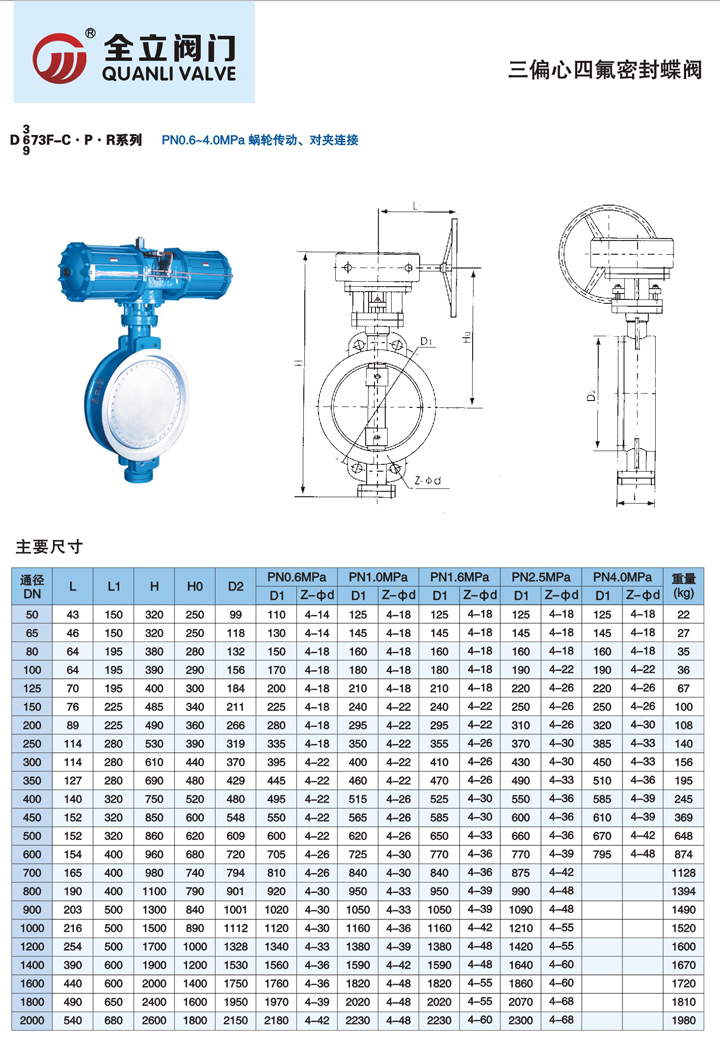

Three eccentric flange butterfly valve D343W

Stem axis at the same time deviate from the center of the disc and the center of the body, and sealing the vice for the butterfly valve into the three eccentric butterfly valve.

Three eccentric butterfly valve, is widely used in medium temperature ≤ 425 ℃ metallurgy, power, petrochemicals, and water supply and drainage and municipal construction and other industrial pipelines, for regulating the flow and load-off fluid use. Material is divided into: cast iron, cast steel, stainless steel, its main features are:

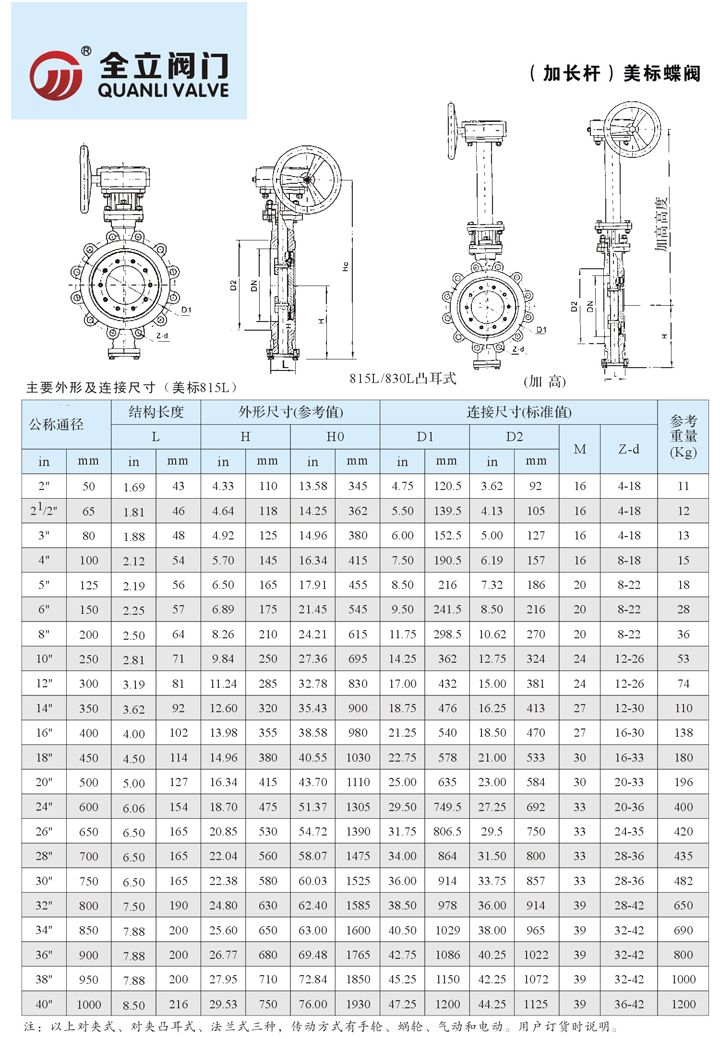

API specifications

As is known, the API 609 has in fact become the international specification for valves used in important industrial lines. The Tritec is fully in full accordance with API609 specifications in the latest 1997 version of the design, manufacture. More importantly, Tritec's basic design is not limited to API a specification, BS5155 ANSI B16.34, ASME SEC VIII and other major specifications can be mapped, which ensures that Tritec in all industrial fields have a place.

Double safety construction

Tritec in strict accordance with API609 specifications, in order to prevent the fluid pressure, temperature caused by the butterfly plate deformation, stem dislocation, sealing surface occlusion, in the upper and lower side of the disc are equipped with two separate thrust ring, Thus ensuring the valve in any condition of the normal work;

At the same time, in order to prevent the unknown reason caused by the stem damage, flying out of the accident caused by two inside and outside the valve design of the two separate stem out of the prevention mechanism, which from the side to ensure the Tritec pressure rating Can be up to 2500 pounds.

No dead zone design

Tritec in the design process, with particular attention to the regulation in the field of application problems, make full use of the three eccentric butterfly valve sealing principle, so that the butterfly valve does not scratch the valve seat switch, the valve stem torque directly through the butterfly plate to seal Surface, that is almost no friction between the butterfly plate and the valve seat phenomenon, thus eliminating the common valve is a common jump phenomenon, the eradication of the valve within the range of low opening due to friction and other unstable factors caused by the regulation This means that the Tritec can enter the controllable area almost from 0 ° to 90 °, and its normal regulation is more than 2 times than that of the general butterfly valve, and the regulation ratio is higher than the highest Can be as high as 100: 1 or more. This is Tritec as a control valve to create a good use of conditions, especially in the large diameter, the high cost of cut-off valve, in addition, the valve can not achieve zero leakage, emergency shutdown in the case of the need to cut- Of the side of the installation of shut-off valve, and Tritec set control and shut down in one, the economic benefits are extremely impressive.

Body valve seat structure

Three eccentric butterfly valve seat mounting structure in two, most of the convenience for the installation of the butterfly plate, but Tritec is the use of the body seat structure, the valve seat installed in the body. The advantage is compared with the butterfly valve seat, greatly reducing the chance of direct contact with the valve seat, thereby reducing the degree of erosion of the valve seat, extending the life of the valve seat.

Thin layer seat structure

Tritec's valve seat is made of stainless steel sheet and graphite sheet. This structure can effectively prevent the impact of micro-solids in the medium and the sealing surface may be caused by thermal expansion occlusion, even if there is little damage, it will not leak , Which in the double eccentric butterfly valve or other three eccentric butterfly valve is unimaginable.

Replaceable seal pairs

Tritec seal can be described as unique, not only the body seat can be replaced, and because the butterfly plate sealing surface and the disc is independent of the butterfly plate sealing surface can also be replaced, that is when the disc sealing surface damage, do not have to To move back to the factory or large-scale decomposition of the valve, just exchange butterfly plate sealing surface can not only greatly reduce maintenance costs, but also greatly reduces maintenance time and maintenance intensity and difficulty.

Balanced fixed structure

From the three-eccentric butterfly valve sealing surface shape characteristics, Tritec seal fixation using a fixed oval-shaped bolt distribution, not only accurate positioning, but also to each bolt are balanced force, eliminate the stress distribution caused by uneven Seal vice loose, leak.

Mobile site

App