National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

Vertical check valve

Location:Home > Vertical check valve

Stainless steel vertical flange check valve H42W

Stainless steel vertical check valve is to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back valve, also known as check valve, check valve, counterflow valve, and back pressure valve. Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reverse, and the container media release. The check valve may also be used on a line in which the supply pressure of the auxiliary system may be increased beyond the system pressure. Check valve can be divided into swing check valve (according to the center of gravity rotation) and the lift check valve (along the axis of movement).

This type of valve works by allowing only the medium to flow in one direction and to prevent directional flow. Usually this valve is automatically working, in a direction under the action of fluid pressure, disc open; flow

Stainless steel vertical check valve body in the opposite direction of flow, by the fluid pressure and the valve flap valve self-acting on the valve seat, which cut off the flow.

One internal thread check valve, butterfly check valve belongs to this type of valve, which includes swing-type check valve and lift check valve. Swing check valve has a hinge mechanism, as well as a door like the valve flap free to lean against the inclined seat surface. In order to ensure that the valve flap to reach the seat surface each time the appropriate position, the valve flap design in the hinge so that the valve flap has enough space to open space, and the valve real, full contact with the valve seat. The valve flap can be made entirely of metal, or it can be covered with leather, rubber, or a synthetic cover, depending on the performance requirements. Swing check valve in the fully open condition, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small. Lift check valve valve seat is located on the valve seat sealing surface. The valve in addition to the valve can be free to lift, the rest of the same as the cut-off valve, the fluid pressure from the valve seat sealing surface lift up, the media return valve leading to the valve seat down and cut off the flow. Depending on the conditions of use, the valve flap may be of the all-metal construction, or may be in the form of a rubber pad or rubber ring mounted on the valve disc holder. Like the cut-off valve, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve swing larger than the swing check valve, and the flow of swing check valve is limited Very little.

A, stainless steel vertical check valve according to its structure and installation can be divided into:

1, stainless steel vertical check valve disc was disc-shaped, around the seat axis of the axis of rotation, because the valve channel into a streamlined, flow resistance than the butterfly check valve is small, suitable for low flow and flow Do not often change the large-caliber occasion, but not suitable for pulsating flow, the sealing performance is less than lift type. Butterfly check valve is divided into single-valve type, double-valve type and more than three types, these three forms are mainly divided by the valve caliber, the purpose is to prevent the media stop flow or back flow, weakening the hydraulic shock.

2, stainless steel vertical check valve: valve flap sliding along the vertical centerline of the check valve, muffler check valve can only be installed in the horizontal pipeline, high-pressure small-caliber check valve disc can be used on a round ball. Muffler check valve body shape and the same stop valve (with the cut-off valve common), so it's fluid resistance coefficient. The structure and cut-off valve is similar to the valve body and the valve with the same stop valve. The upper part of the valve flap and the lower part of the valve cover are processed with a guide sleeve. The valve flap can be freely lifted and lowered in the valve guide. When the medium is downstream, the valve flap is opened by the medium thrust. When the medium stops flowing, Dropping down on the valve seat, from the media to prevent backwash effect. The inlet and outlet channel of the straight-type butterfly check valve is perpendicular to the direction of the seat channel. The vertical lift-type check valve has the same direction of the medium inlet and outlet channel as the valve seat channel, and its flow resistance is smaller than the straight-through type.

3, stainless steel vertical check valve: valve around the valve seat within the pin rotation of the check valve. Disc check valve is simple, can only be installed in the horizontal pipe, sealing better.

4, stainless steel vertical check valve: valve flap sliding along the centerline of the valve body. Pipeline check valve is an emerging valve, its small size, light weight, processing technology is good, is one of the development direction of the check valve. But the fluid drag coefficient is slightly larger than the swing check valve.

5, compression-type check valve: This valve is used as boiler feed water and steam cut off valve, it has a lift check valve and stop valve or angle valve integrated function.

In addition, there are some not applicable to the installation of the pump outlet check valve, such as the bottom valve, spring type, Y type and other check valves.

B, stainless steel vertical check valve uses and performance specifications:

The valve for industrial pipe to prevent the flow of media back to the device.

Design and manufacturing | GB/T12235 | |

Connection end dimensions | Structure length | GB/T12221 |

Flange dimensions | JB/T79 | |

Inspection and testing | JB/T9092 | |

material | Carbon steel | GB/T12229 |

stainless steel | GB/T12230 | |

alloy steel | Q/ZB66 | |

Logo | GB/T12220 | |

Availability | JB/T7928 | |

model | Nominal pressure | test pressure | Operating temperature(℃) | ||

strength (water) Mpa | seal (Water) air (Mpa) | Low pressure seal (air) Mpa | |||

H42W-16 | 1.6 | 2.4 | 1.8 | 0.6 | ≤200 |

H42W-25 | 2.5 | 3.8 | 2.8 | 0.6 | ≤200 |

H42W-40 | 4.0 | 6.0 | 4.4 | 0.6 | ≤200 |

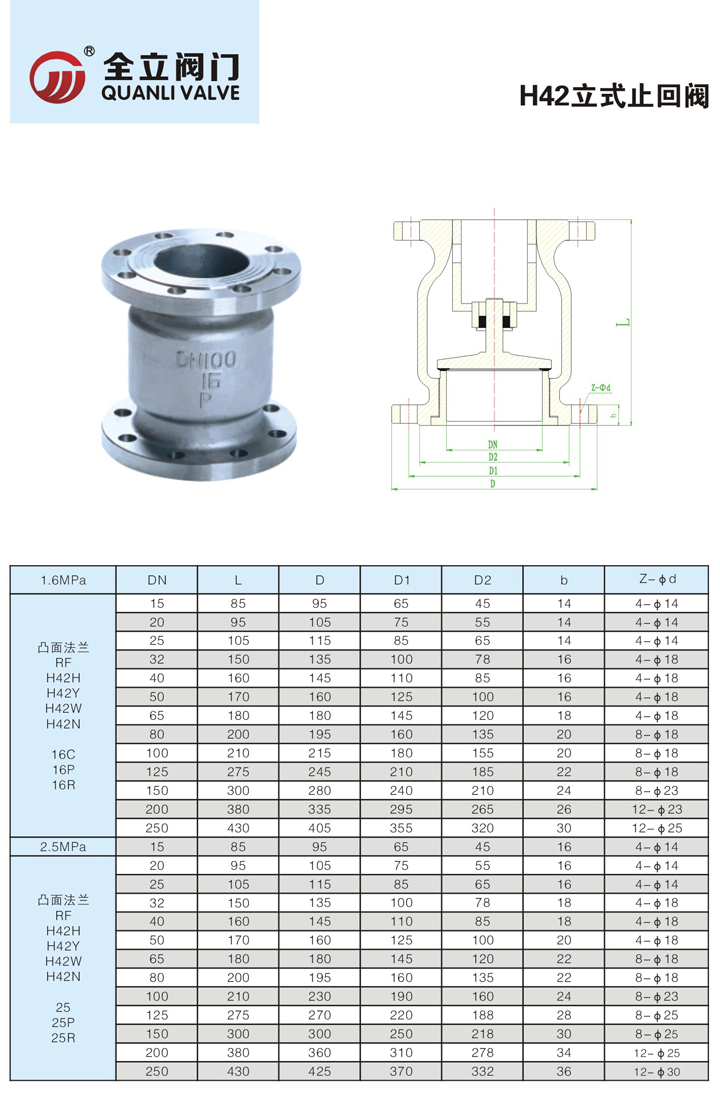

Main connection dimensions and dimensions

Model | DN | size(mm) | ||||||

L | D | D1 | D2 | H | b | Z-Φd | ||

H42W-16 | 15 | 130 | 95 | 65 | 45 | 77 | 14 | 4-14 |

20 | 150 | 105 | 75 | 55 | 77 | 14 | 4-14 | |

25 | 160 | 115 | 85 | 65 | 80 | 16 | 4-14 | |

32 | 180 | 135 | 100 | 78 | 85 | 16 | 4-18 | |

40 | 200 | 145 | 110 | 85 | 95 | 16 | 4-18 | |

50 | 230 | 160 | 125 | 100 | 105 | 16 | 4-18 | |

65 | 290 | 180 | 145 | 120 | 120 | 18 | 4-18 | |

80 | 310 | 195 | 160 | 135 | 130 | 20 | 8-18 | |

100 | 350 | 215 | 180 | 155 | 140 | 20 | 8-18 | |

125 | 400 | 245 | 210 | 185 | 155 | 22 | 8-18 | |

150 | 480 | 280 | 240 | 210 | 180 | 24 | 8-23 | |

200 | 600 | 335 | 295 | 265 | 215 | 26 | 12-23 | |

H42W-25 | 15 | 130 | 95 | 65 | 45 | 77 | 16 | 4-14 |

20 | 150 | 105 | 75 | 55 | 80 | 16 | 4-14 | |

25 | 160 | 115 | 85 | 65 | 85 | 16 | 4-14 | |

32 | 180 | 135 | 100 | 78 | 95 | 18 | 8-18 | |

40 | 200 | 145 | 110 | 85 | 105 | 18 | 8-18 | |

50 | 230 | 160 | 125 | 100 | 120 | 20 | 8-18 | |

65 | 290 | 180 | 145 | 120 | 130 | 212 | 8-18 | |

80 | 310 | 195 | 160 | 135 | 140 | 22 | 8-18 | |

100 | 350 | 230 | 190 | 160 | 155 | 24 | 8-23 | |

125 | 400 | 270 | 220 | 188 | 180 | 28 | 8-25 | |

150 | 480 | 300 | 250 | 218 | 215 | 30 | 8-25 | |

200 | 600 | 360 | 310 | 278 | 973 | 34 | 12-2 | |

Mobile site

App