National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

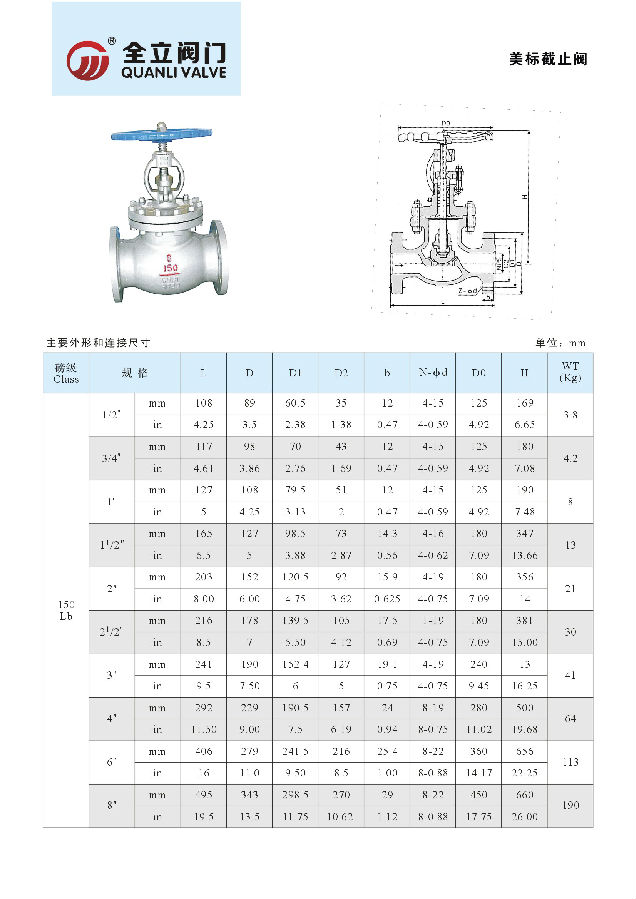

American standard globe valve

Location:Home > American standard globe valve

Stainless steel American standard cut - off valve J41W

American Standard cut-off valve in the pipeline is mainly used for cutting, distribution and change the flow direction of the medium. American Standard cut-off valve is widely used in recent years, a new type of valve, which has the following advantages:

1. The fluid resistance is small, the resistance coefficient and the same length of the pipe segment equal.

2. Simple structure, small size, light weight.

3. Close and reliable, the current valve sealing surface material widely used plastic, sealing, and in the vacuum system has also been widely used.

4. Easy to operate, open and close quickly, from full open to fully closed as long as the rotation 90 °, easy remote control.

5. Easy maintenance, gate valve structure is simple, the seals are generally active, the demolition of replacement are more convenient.

6. In the fully open or fully closed, the ball and seat sealing surface and medium isolation, the media through, it will not cause corrosion of the valve sealing surface.

7. Wide range of applications, from small to a few millimeters in diameter, large to a few meters, from high vacuum to high pressure can be applied, the ball rotated 90 degrees, in the import and export should be spherical all appear to cut off the flow.

1, open and close without friction. This feature completely solved the traditional [/ wiki] due to the friction between the sealing surface affect the sealing problem.

2, the top-loading structure. On the pipeline installed on the valve can be directly on-line inspection and maintenance, can effectively reduce the device parking, reduce costs.

3, single seat design. The elimination of the valve chamber medium due to abnormal boost the impact of the use of security issues.

4, low torque design. Special structural design of the stem, just with a small handle can easily open and close the valve.

5, wedge-shaped seal structure. Valve is provided by the mechanical stem valve, the ball wedge pressure on the seat and sealed to the valve sealing performance from the pressure changes in the pipeline, in a variety of conditions have a reliable guarantee of performance.

6, the sealing surface of the self-cleaning structure. When the ball away from the valve seat, the fluid in the pipeline along the ball sealing surface into a 360 ° uniform, not only eliminates the high-speed fluid on the seat of the local erosion, but also washed away the sealing surface of the aggregate, to achieve the purpose of self-cleaning .

Such valves should be installed horizontally on the pipe

150Lb External and connecting dimensions (mm)

NPS | Unit | L | D | C | G | T | n-Ф | W | H | |

in | mm | |||||||||

1/2〞 | 15 | mm | 108 | 89 | 60.5 | 35 | 12 | 4-15 | 125 | 169 |

in | 4.25 | 3.5 | 2.38 | 1.38 | 0.47 | 4-0.59 | 4.92 | 6.65 | ||

3/4〞 | 20 | mm | 117 | 98 | 70 | 43 | 12 | 4-15 | 125 | 180 |

in | 4.61 | 3.86 | 2.76 | 1.69 | 0.47 | 4-0.59 | 4.92 | 7.08 | ||

1〞 | 25 | mm | 127 | 108 | 79.5 | 51 | 12 | 4-15 | 125 | 190 |

in | 5 | 4.25 | 3.13 | 2 | 0.47 | 4-0.59 | 4.92 | 7.48 | ||

11/2〞 | 40 | mm | 165 | 127 | 98.5 | 73 | 14.3 | 4-16 | 180 | 347 |

in | 6.5 | 5 | 3.88 | 2.88 | 0.56 | 4-0.62 | 7.09 | 13.66 | ||

2〞 | 50 | mm | 178 | 152 | 120.5 | 92 | 15.9 | 4-19 | 180 | 365 |

in | 7 | 6 | 4.75 | 3.62 | 0.625 | 4-0.75 | 7.09 | 14 | ||

21/2〞 | 65 | mm | 190 | 178 | 139.5 | 105 | 17.5 | 4-19 | 240 | 381 |

in | 7.5 | 7 | 5.50 | 4.12 | 0.69 | 4-0.75 | 9.45 | 15.00 | ||

3〞 | 80 | mm | 203 | 190 | 152.4 | 127 | 19.1 | 4-19 | 280 | 413 |

in | 8 | 7.5 | 6 | 5 | 0.75 | 4-0.75 | 11.02 | 16.25 | ||

4〞 | 100 | mm | 229 | 229 | 190.5 | 157 | 23.9 | 8-19 | 280 | 500 |

in | 9 | 9 | 7.5 | 6.19 | 0.94 | 8-0.75 | 11.02 | 19.68 | ||

6〞 | 150 | mm | 394 | 279 | 241.5 | 216 | 26 | 8-22 | 360 | 656 |

in | 15.5 | 11.00 | 9.50 | 8.5 | 1.02 | 8-0.88 | 14.14 | 22.25 | ||

8〞 | 200 | mm | 457 | 343 | 298.5 | 270 | 29 | 8-22 | 450 | 660 |

in | 18.00 | 13.50 | 11.75 | 10.62 | 1.12 | 8-0.88 | 17.75 | 26.00 | ||

Test pressure 300LB

Type | Mpa | PSI |

Shell test | 7.7 | 1125 |

Sealing test(WATER) | 5.8 | 815 |

Sealing test(AIR) | 5-7巴 Bar | |

Test pressure 600LB

Type | Mpa | PSI |

Shell test | 15.4 | 2225 |

Sealing test(WATER) | 5.8 | 1628 |

Sealing test(AIR) | 5-7 Bar | |

300Lb External and connecting dimensions (mm)

NPS | Unit | L | D | T | G | C | n-Ф | W | H | |

in | mm | |||||||||

1/2〞 | 15 | mm- | 152 | 95 | 15 | 35 | 66.5 | 4-15 | 125 | 190 |

in | 5.98 | 3.74 | 0.59 | 1.38 | 2.62 | 4-0.59 | 4.92 | 7.48 | ||

3/4〞 | 20 | mm | 178 | 117 | 16 | 43 | 82.5 | 4-19 | 125 | 212 |

in | 7 | 4.61 | 0.62 | 1.69 | 3.25 | 4-0.75 | 4.92 | 8.35 | ||

1〞 | 25 | mm | 203 | 124 | 18 | 51 | 89 | 4-19 | 160 | 231 |

in | 8 | 4.9 | 0.71 | 2 | 3.5 | 4-0.75 | 6.2 | 9.1 | ||

11/2〞 | 40 | mm | 229 | 156 | 20.7 | 73 | 114.5 | 4-22 | 200 | 391 |

in | 9 | 6.12 | 0.81 | 2.88 | 4.51 | 4-0.88 | 7.87 | 12.43 | ||

2〞 | 50 | mm | 267 | 165 | 22.3 | 92 | 127 | 8-19 | 200 | 406 |

in | 10.5 | 6.5 | 0.88 | 3.62 | 5 | 8-0.75 | 7.87 | 16.00 | ||

21/2〞 | 65 | mm | 292 | 190 | 25.4 | 105 | 149 | 8-22 | 240 | 457 |

in | 11.50 | 7.5 | 1 | 4.12 | 5.87 | 8-0.88 | 9.45 | 18.00 | ||

3〞 | 80 | mm | 318 | 210 | 28.5 | 127 | 168.5 | 8-22 | 280 | 470 |

in | 12.50 | 8.25 | 1012 | 5 | 6.62 | 8-0.88 | 11.02 | 18.50 | ||

4〞 | 100 | mm | 356 | 254 | 31.8 | 157 | 200 | 8-22 | 320 | 590 |

in | 14.00 | 10 | 1.25 | 6.19 | 7.88 | 8-0.88 | 12.60 | 22.30 | ||

6〞 | 150 | mm | 444 | 318 | 36.6 | 216 | 270 | 12-22 | 500 | 711 |

in | 17.50 | 12.5 | 1.44 | 8.5 | 10.62 | 12-0.88 | 19.68 | 28.00 | ||

8〞 | 200 | mm | 559 | 381 | 41.3 | 270 | 330 | 12-25 | 500 | 750 |

in | 22.00 | 15 | 1.62 | 10.62 | 13.00 | 12-1 | 19.68 | 29.50 | ||

600Lb External and connecting dimensions (mm)

NPS | Unit | L | D | T | G | C | n-Ф | W | H | |

in | mm | |||||||||

1/2〞 | 15 | mm- | 152 | 95 | 15 | 35 | 66.5 | 4-15 | 160 | 285 |

in | 5.98 | 3.74 | 0.59 | 1.38 | 2.62 | 4-0.59 | 0.62 | 11.22 | ||

3/4〞 | 20 | mm | 178 | 117.5 | 16 | 43 | 82.5 | 4-19 | 160 | 285 |

in | 7 | 4.16 | 0.62 | 1.69 | 3.25 | 4-0.75 | 0.62 | 11.22 | ||

1〞 | 25 | mm | 203 | 124 | 18 | 51 | 89 | 4-19 | 160 | 313 |

in | 8 | 4.9 | 0.71 | 2 | 3.5 | 4-0.75 | 0.62 | 12.32 | ||

11/2〞 | 40 | mm | 229 | 156 | 23 | 73 | 114.5 | 4-22 | 240 | 365 |

in | 9 | 6.12 | 0.91 | 2.88 | 4.51 | 4-0.88 | 9.45 | 14.17 | ||

2〞 | 50 | mm | 267 | 165 | 25 | 92 | 127 | 8-19 | 240 | 444 |

in | 10.5 | 6.5 | 1.00 | 3.62 | 5 | 8-0.75 | 9.45 | 17.50 | ||

21/2〞 | 65 | mm | 292 | 190 | 29 | 105 | 149 | 8-22 | 240 | 483 |

in | 11.50 | 7.5 | 1.12 | 4.12 | 5.87 | 8-0.88 | 9.45 | 19 | ||

3〞 | 80 | mm | 318 | 210 | 32 | 127 | 168.5 | 8-22 | 280 | 533 |

in | 12.50 | 8.25 | 12.5 | 5 | 6.62 | 8-0.88 | 11.20 | 21 | ||

4〞 | 100 | mm | 356 | 273 | 38.0 | 157 | 216 | 8-25 | 360 | 622 |

in | 14.00 | 10.75 | 1.5 | 6.19 | 8.5 | 8-1.00 | 14.17 | 24.50 | ||

6〞 | 150 | mm | 444 | 356 | 47.7 | 216 | 292 | 12-29 | 500 | 800 |

in | 17.50 | 14 | 1.88 | 8.5 | 11.5 | 12-1.14 | 19.68 | 31.50 | ||

8〞 | 200 | mm | 559 | 419 | 55.6 | 270 | 349 | 12-32 | 55. | 927 |

in | 22.00 | 16.50 | 2.19 | 10.62 | 13.75 | 12-1.25 | 21.65 | 36.50 | ||

Mobile site

App