National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

American standard gate valve

Location:Home > American standard gate valve

American standard stainless steel gate valve Z41W Z40W

Gate valve (gate valve) opening and closing parts is the gate, the direction of movement of the gate and the direction of the fluid perpendicular to the gate valve can only be fully open and fully closed, can not be adjusted and throttling. Gate has two sealing surfaces, the most common mode of the two gate valve sealing surface to form a wedge, wedge angle varies with the valve parameters, usually 50, the medium temperature is not high when the 2 ° 52 '. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce trace deformation of the gate to improve its technology to make up the angle of the sealing surface in the process of generating the deviation, the gate The plate is called the elastic shutter. Stainless steel gate valve material is divided into 304 stainless steel gate valve, 316 stainless steel gate valve, 321 stainless steel gate valve. Said method is: Z41H-16P.

The type of stainless steel gate valve, according to the sealing surface configuration can be divided into wedge gate type gate valve and parallel gate type gate valve, wedge gate type gate valve can be divided into: single gate type, double gate type and elastic gate type; parallel gate type gate valve Can be divided into single-gate type and double-gate type. According to the stem of the screw position, can be divided into two kinds of open-gate valve and the dark rod gate valve. This type of valve in the pipeline should generally be installed horizontally.

Stainless steel gate valve structure Open the valve, when the gate lifting height is equal to 1: 1 times the valve diameter, the fluid channel is fully open, but in operation, this position can not be monitored. The actual use, is based on the vertex of the valve stem as a sign, that is fixed position, as its full open position. In order to consider the phenomenon of temperature change lock phenomenon, usually in the open to the vertex position, and then back 1 / 2-1 laps, as a fully open valve position. Therefore, the valve fully open position, according to the gate position (ie stroke) to determine.

Some valve, stem nut located in the gate, the hand wheel rotation driven stem rotation, leaving the gate lift, this valve is called the rotary rod gate valve, or called the dark bar.

Gate valve with the valve stem with a straight line movement, called the lift bar valve (also known as the Ming Barrier valve). Trapezoidal threads are usually provided on the lift rods. The rotary motion is changed to linear motion through the nut on the top of the valve and the guide groove on the valve body, ie the operating torque is changed to the operating thrust. Sealing surface can only rely on medium pressure to seal, that is, relying on the media pressure to the gate of the sealing surface to the other side of the valve seat to ensure the sealing surface of the seal, which is self-sealing. Most of the gate valve is forced seal, that is, the valve is closed, to rely on external force to force the gate pressure to the valve seat to ensure the sealing surface of the seal.

【Product Usage】

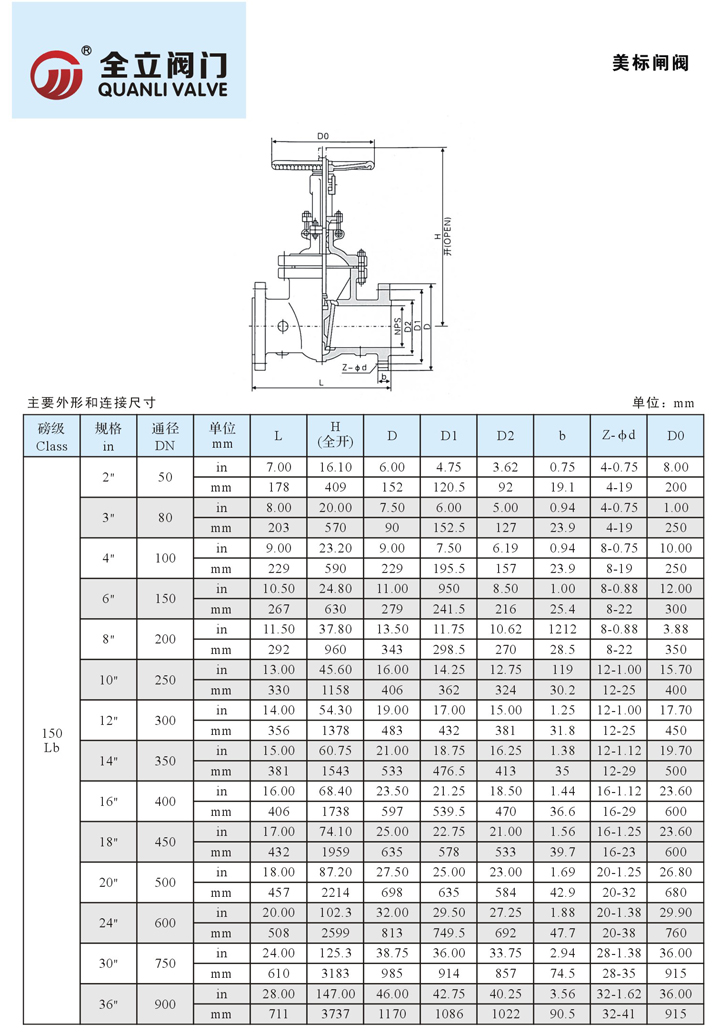

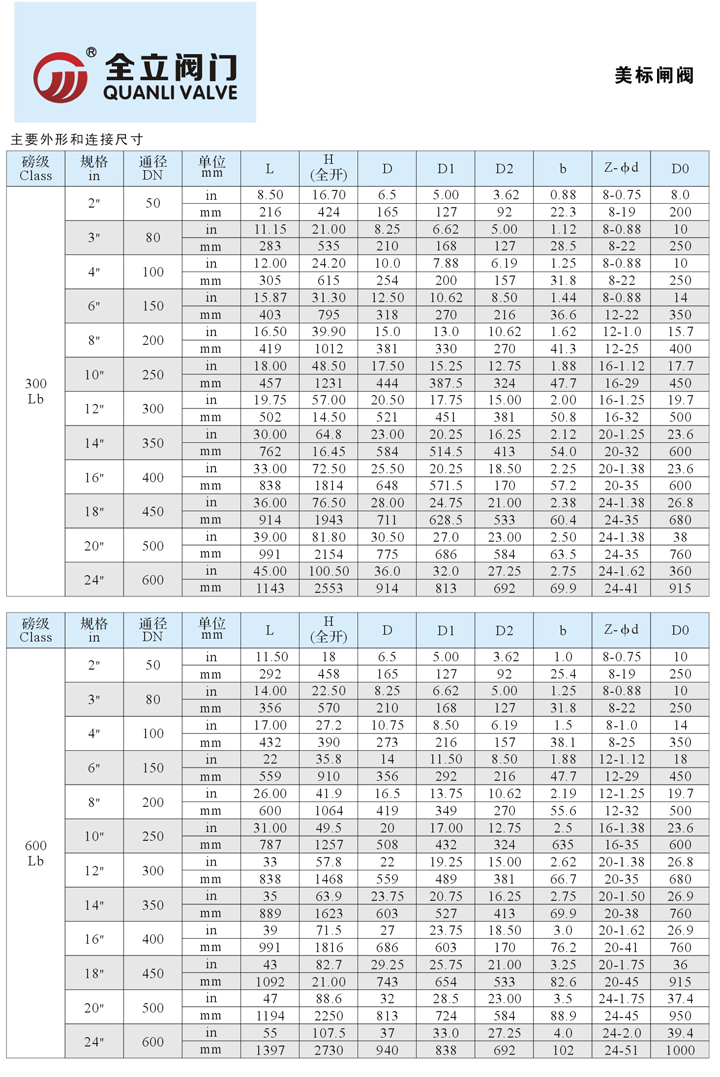

Z41H / W American standard gate valve for ANSI Class150 ~ 2500, PN20 ~ 42, JIS10 ~ 20K, operating temperature -29 ~ 425 ℃ (carbon steel) and -40 ~ 500 ℃ (stainless steel) Or turn on the media in the line. Through the use of different materials, can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidizing media and urea and other media.

Features: ① product design and manufacture in line with foreign advanced standards, reliable sealing, excellent performance. ② compact and reasonable structure design, handsome in appearance. ③ wedge-type flexible gate structure, large diameter set rolling bearings, opening and closing easily. ④ The material of the valve body is complete, the packing and the gasket are matched according to the actual working condition or the user's requirement. It is suitable for all kinds of pressure, temperature and medium working condition. ⑤ use of a variety of domestic and foreign standard flange flange and flange sealing surface to meet a variety of engineering needs and user requirements.

【Product performance standards】

Design and manufacture:

Flange size: ANSI B16.5

Structure length: ANSI B16.10

Pressure to Temperature: ANSI B16.34

Inspection and testing: API 598

【Product Performance Specification】

Mobile site

App