National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

Electric valve

Location:Home > Electric valve

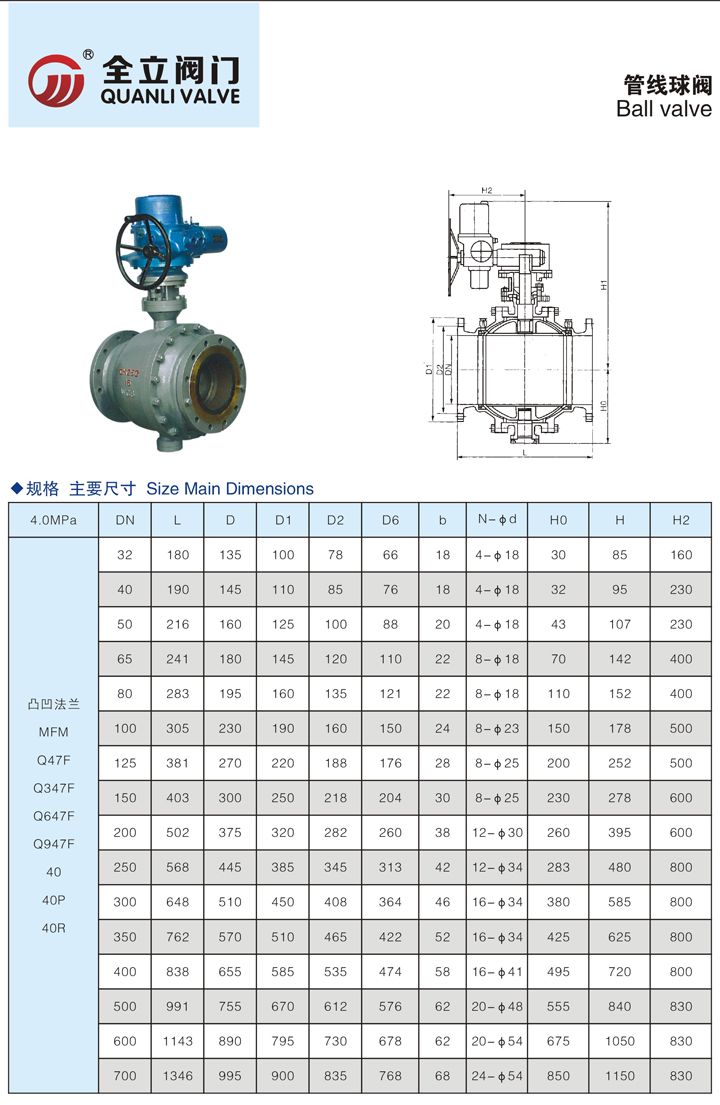

Electric flange ball valve Q941F

Electric ball valve (English name: Electronic Ball Valve) by the electric actuator and ball valve together constitute electric ball valve.

Is an industrial automation process control of a pipeline pressure components, usually used for pipeline medium remote on, off (on, cut off the media) control. Electric ball valve standard GB / T21465-2008 "valve terminology" is defined as: opening and closing pieces (ball) driven by the stem, and the axis of rotation around the valve stem for the movement of the valve. Mainly used to cut off or connected to the medium in the pipeline, can also be used for fluid regulation and control, including hard-sealed V-type ball valve V-core ball and carbide welding between the metal seat with a strong shear Particularly suitable for containing fiber, small solid particles and other media. Electric ball valve is divided into electric flange ball valve, electric ball valve, electric welding ball valve, electric wire deduction ball valve. According to the sealed form is also divided into soft sealed electric ball valve, hard sealed electric ball valve.

Ball valve, ball valve, ball valve, ball valve, three-way ball valve, stainless steel ball valve, forged ball valve, unloading ball valve, anti-sulfur ball valve, three-way ball valve, pneumatic ball valve, electric ball valve, card Sets of ball valves, welding ball valve, flange ball valve, wire mouth ball valve.

Floating ball: Ball valve ball is floating, in the medium under pressure, the ball can produce a certain displacement and pressed on the export side of the sealing surface, to ensure that the export side of the seal. Floating ball valve structure is simple, good sealing, but the ball bear the load of the working medium all passed to the export ring, so to consider whether the material can withstand the ball ring media work load, by the higher pressure shock , The sphere may shift. This structure, generally used in low-pressure ball valve.

Fixed Ball: The ball of the ball is fixed, do not move after compression. Fixed ball valve with a floating seat, subject to media pressure, the seat movement, so that the ring pressed on the ball to ensure that the seal. Usually with the ball on the upper and lower shaft with bearings, operating torque is small, suitable for high-pressure and large diameter valves. In order to reduce the operating torque of the ball valve and increase the reliability of the seal, lubricating oil to form a layer of oil film, which enhances the sealing, but also reduces the operating torque, more suitable for high-pressure large-diameter ball valve.

Elastic ball: The sphere of the ball valve is elastic.

Ball and seat seals are made of metal materials, sealing a great pressure to rely on the media itself has been less than the pressure of the sealing requirements, you must exert external force. This valve is suitable for high temperature and high pressure medium. Elastic sphere is in the lower end of the inner wall of the ball to open an elastic groove, and get elastic. When closing the channel, with the stem of the wedge-shaped head so that the ball up and the valve seat pressed to seal. Before turning the ball first release the wedge-shaped head, the ball will be restored to its original shape, so that the ball and the valve seat between a small gap, can reduce the sealing surface friction and operating torque.

Mobile site

App