National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

National free service hotline:400-879-6552

Add to Favorites | Set to the home page | Sitemap | Contact

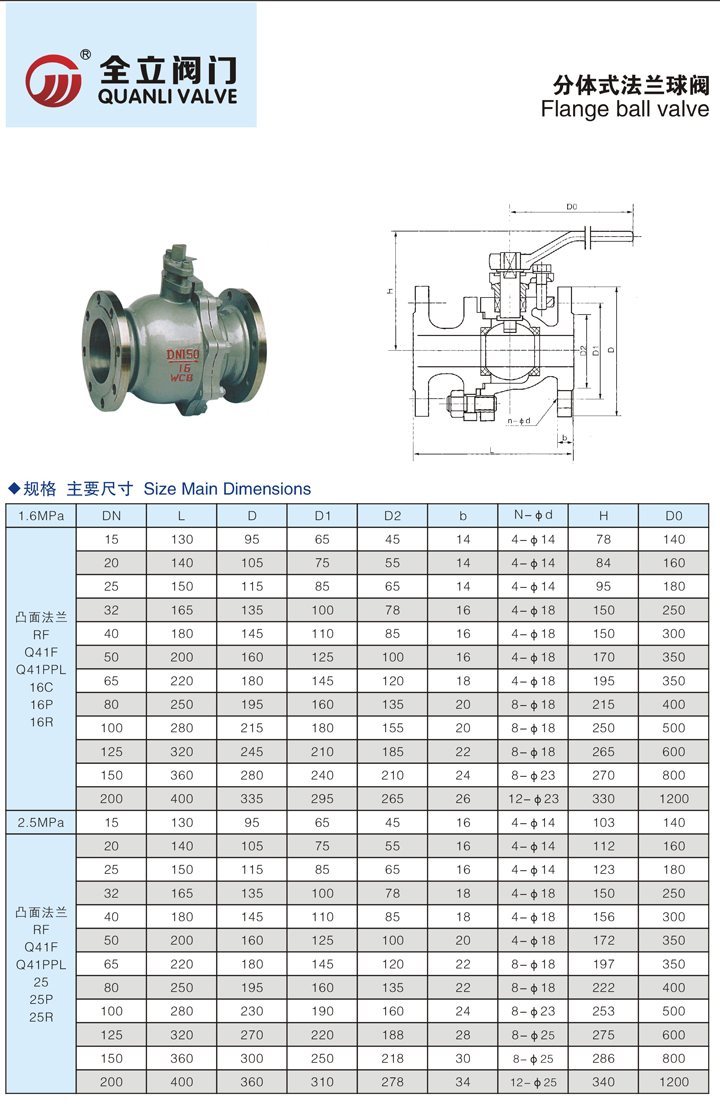

Flange ball valve

Location:Home > Flange ball valve

Soft sealing flange stainless steel ball valve Q41F

Floating soft sealing ball valve is used in various pipes of Class150 ~ Class1500, PN16 ~ PN63, JIS10K ~ JIS20K, for cutting off or connecting the medium in the pipeline, use different materials, can be applied to water, steam, oil , Liquefied gas, natural gas, gas, nitric acid, acetic acid, oxidizing medium, urea and other media.

In a variety of valves, the ball valve flow resistance minimum, the full diameter ball valve is opened, the ball channel, the valve body channel and the diameter and diameter of the connection, the media can almost no loss of flow

Ball valve can be fully rotated 90 ° fully closed, open and close quickly. Compared with the same specifications of the gate valve, globe valve, ball valve small size, light weight, easy to install the pipe.

The main features of the ball valve

The main features of the ball valve itself is compact, small fluid resistance, the full diameter of the basic flow valve is no resistance. Easy to repair and maintenance, suitable for water, solvents, acids and natural gas and other general working medium, and the sealing surface and the spherical surface is often closed, easy to be medium erosion, easy operation and maintenance, It is also suitable for medium working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. It is widely used in various industries. When the valve is fully open or fully closed, the sealing surface of the ball and valve seat is isolated from the medium. , Does not cause corrosion of the valve sealing surface for a wide range of diameter from small to a few millimeters, large to a few meters, from high vacuum to high pressure can be applied. Ball valve body can be integrated, it can be combined.

Third, the ball is divided into floating ball valve and fixed type two types of ball valves.

1, floating ball valve: its main feature is the ball without supporting the axis of the ball to the valve at both ends of the valve seat for support. Stem and the ball for the active link, so the ball is the ball valve seat clamping them were "floating" state.

2, fixed ball valve: It is characterized by the ball and the upper and lower stem connected together, the ball can be along the valve axis perpendicular to the axis of rotation, but not along the channel axis. Therefore, the fixed ball ball valve torque, valve seat deformation is small, stable sealing performance, long life, suitable for high pressure, large diameter of the occasion.

Fourth, the role of the ball valve

Mainly used for switching, cutting off or connected to the pipeline of media, can also be used for fluid regulation and control.

Fifth, the ball valve applications

Chemical, petrochemical, oil, paper, mining, electricity, liquefied petroleum gas, food, pharmaceutical, water supply and drainage, municipal, machinery and equipment supporting the electronics industry, urban construction and other fields.

6, for media

Water, solvents, acids, natural gas, oxygen, hydrogen peroxide, methane and ethylene.

7, ball valve characteristics

The valve structure is compact, reliable sealing, simple structure, easy maintenance, sealing surface and spherical surface in the closed state, not easy to be medium erosion, easy operation and maintenance.

Eight, the ball valve sealing material

Ball valve sealing performance depends largely on the material of the seal, the correct and reasonable choice of sealing materials to ensure the performance of ball valve, extend the useful life of great significance. The material requirements have a high wear resistance and resistance to solubility, should have a high enough strength, can withstand long-term fluid pressure, and can be disassembled many times, flexibility and plasticity, sliding friction coefficient and low expansion coefficient, Abrasion resistance and excellent self-lubricating properties, and has good impermeability and non-hygroscopicity, can be cold and heat resistance and rapid changes in temperature, and a good thermal conductivity. Sealing materials are non-metallic and metal sealing materials two.

1. Non-metallic sealing materials: commonly used fiber materials, rubber, engineering plastics and carbon materials. These materials have a low modulus of elasticity and a high Poisson coefficient, therefore, under a low sealing force, that is able to obtain large elastic-plastic deformation, the gap may have a better penetration of the role of packing.

2. Metal sealing materials: commonly used in aluminum, copper and carbide, aluminum bronze commonly used in the manufacture of ball valves with flange gaskets, carbide is used for high-temperature ball valve seat and the sphere of the sealing surface.

Mobile site

App